Treatment with TURBOCOAG® is an excellent alternative to deep well injection disposal and also reduces operational costs and preserves resources.

Avivid’s Electrocoagulation Advantages:

|

TURBOCOAG® FEATURES:

|

FRACK POND WEST VIRGINIA

Frack water from a storage pond in West Virginia was treated on April 15th through April 17th, 2019 and tested on April 15th and April 18th.

The water was initially treated with the TurboCoag® 1-GPM bench scale reactor to determine appropriate treatment levels and polymer dosages.

Water was then treated at different dosage levels using the larger reactor in the pilot trailer known as TurboCoag® IV.

The treated water was held in four 1500-gallon storage tanks. The water from each tank was tested for residual iron levels, which were compared to the iron levels in the untreated water.

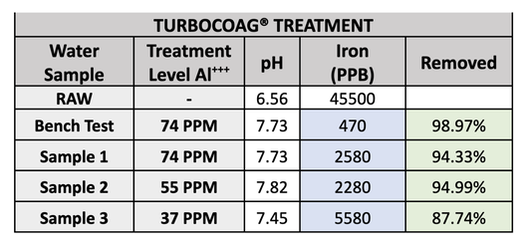

The following tables provide data from these treatments.

The water was initially treated with the TurboCoag® 1-GPM bench scale reactor to determine appropriate treatment levels and polymer dosages.

Water was then treated at different dosage levels using the larger reactor in the pilot trailer known as TurboCoag® IV.

The treated water was held in four 1500-gallon storage tanks. The water from each tank was tested for residual iron levels, which were compared to the iron levels in the untreated water.

The following tables provide data from these treatments.

ADDITIONAL TURBOCOAG® FEATURESARGO MINE RESULTS AFTER TREATMENT WITH TURBOCOAG®

|

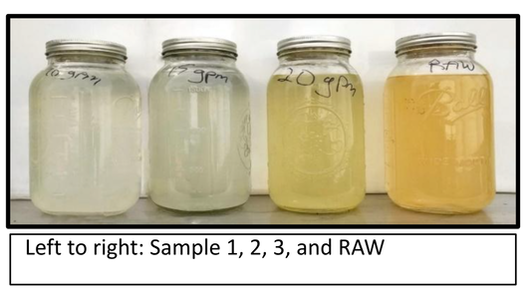

The settling tanks, shown far left, hold the treated water from which the above samples were taken. These tanks are 116 inches high containing 1500 gallons each.

|

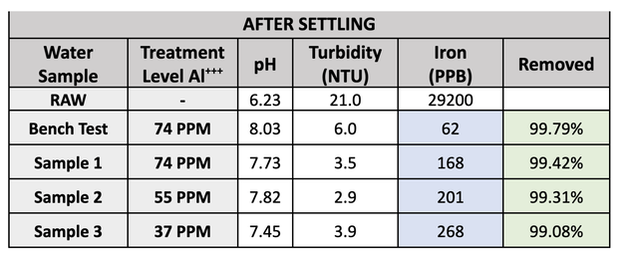

The following table shows lab test results after the water samples taken from the storage tanks after settling.