TURBOCOAG® IS IDEALLY SUITED FOR REMEDIATING AMD.

TURBOCOAG® remediates:

|

TURBOCOAG® FEATURES

|

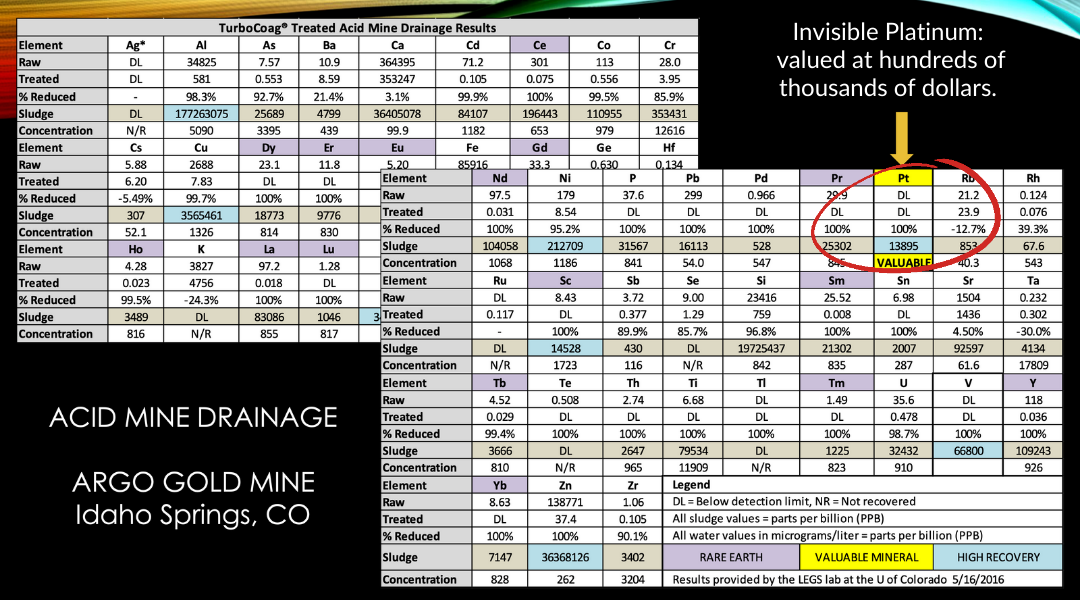

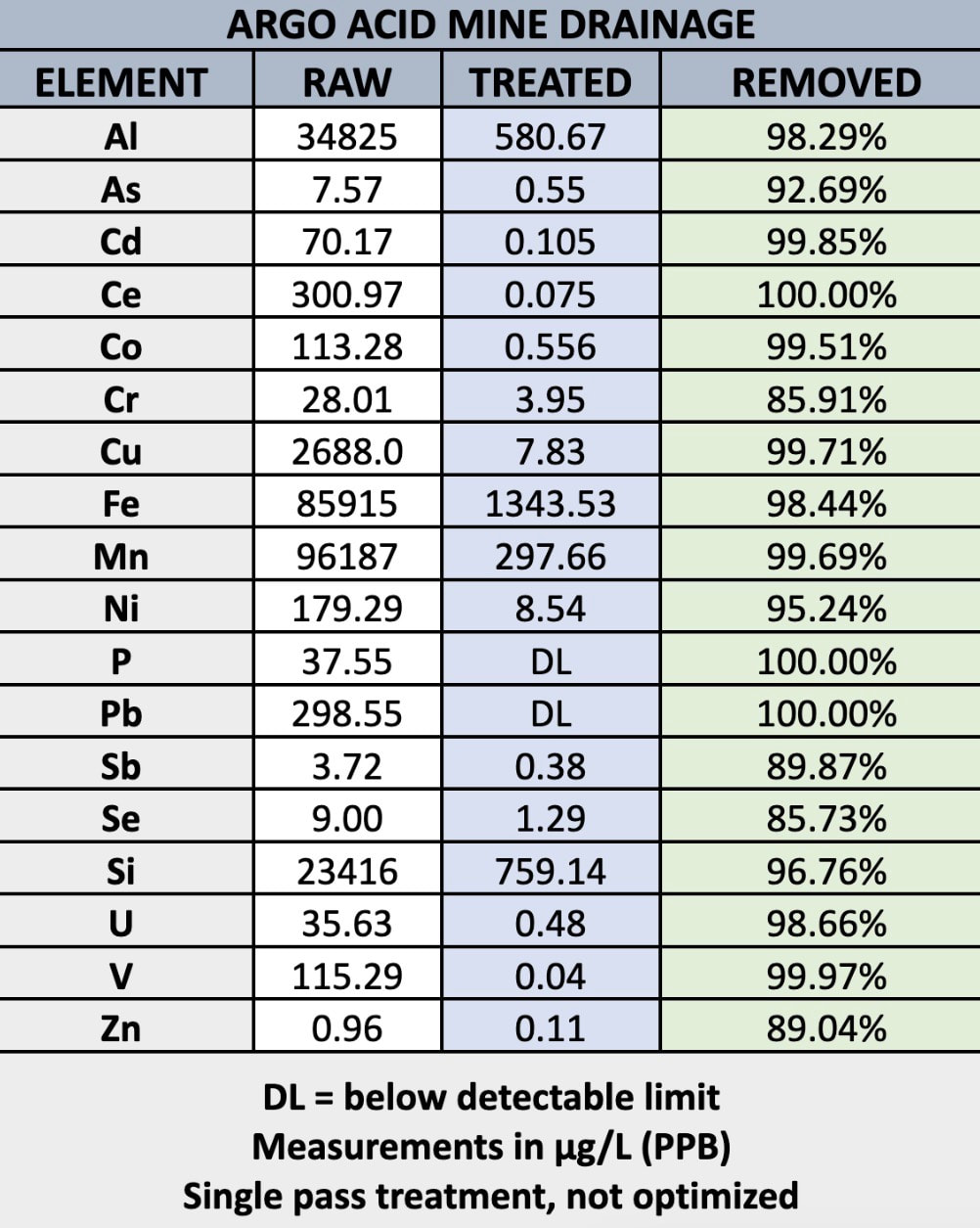

CASE STUDY: ARGO MINE

The Argo Mine west of Denver flows acid mine water at approximately 300 Gallons Per Minute.

The current lime treatment raises the pH of the water from approximately pH 2 to 11, precipitates out heavy metals and generates 3.2 tons of sludge daily, all of which is trucked to a nearby landfill for disposal.

Avivid processed a sample from the Argo mine and sent the treated water to a third-party laboratory for verification of our TurboCoag® treatment results.

The results showed TurboCoag® significantly reduced the metals in all tests, meeting or exceeding the EPA release standard. All heavy metals were sequestered in the heavy metal precipitate sludge as expected. The sludge - of which there was significantly less than with the current treatment and which passes the toxicity characteristic leaching procedure (TCLP)—can be disposed of in any landfill while the treated water can then be released to the environment.

In addition, the sludge is roughly 50% metal and can be mined directly for lost minerals and metals.

The current lime treatment raises the pH of the water from approximately pH 2 to 11, precipitates out heavy metals and generates 3.2 tons of sludge daily, all of which is trucked to a nearby landfill for disposal.

Avivid processed a sample from the Argo mine and sent the treated water to a third-party laboratory for verification of our TurboCoag® treatment results.

The results showed TurboCoag® significantly reduced the metals in all tests, meeting or exceeding the EPA release standard. All heavy metals were sequestered in the heavy metal precipitate sludge as expected. The sludge - of which there was significantly less than with the current treatment and which passes the toxicity characteristic leaching procedure (TCLP)—can be disposed of in any landfill while the treated water can then be released to the environment.

In addition, the sludge is roughly 50% metal and can be mined directly for lost minerals and metals.

ARGO MINE RESULTS AFTER TREATMENT WITH TURBOCOAG® |

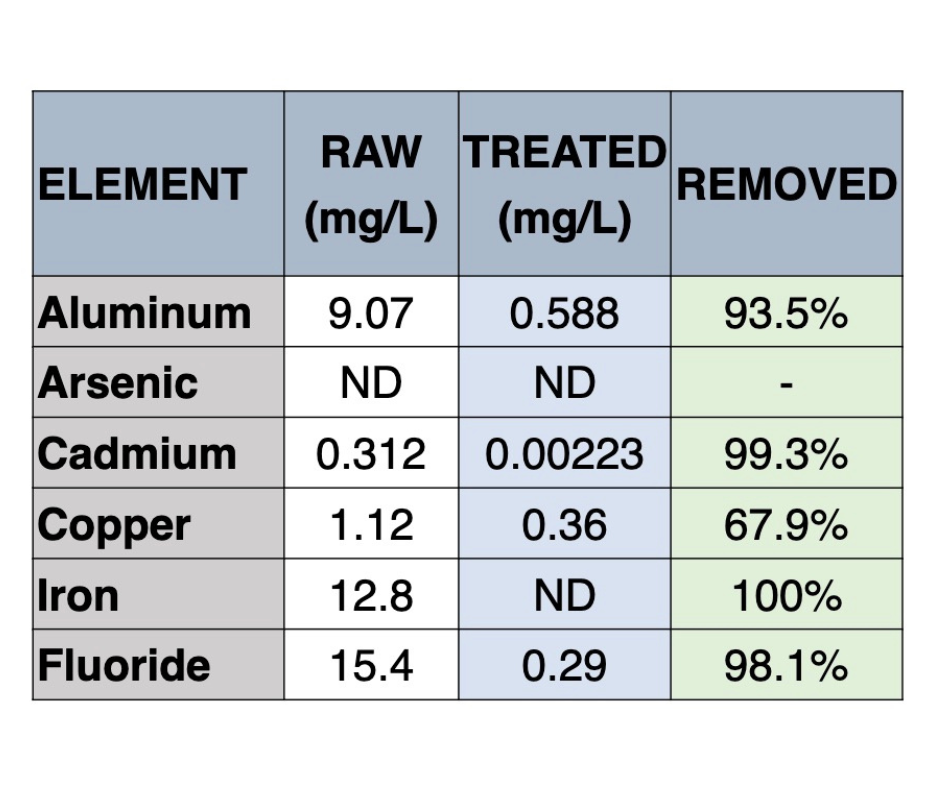

ADDITIONAL TURBOCOAG® FEATURES

TURBOCOAG® also removes Fluoride effectively. |

For more information about how TURBOCOAG® can work for you read our case studies and white papers: