TURBOCOAG® IS GREAT FOR LEACHATE

- Leachate water typically runs between a pH of 6 to a pH 8.5. The optimum pH level for TurboCoag® operation is 6 to 8 which suggests pH adjustment may be unnecessary for processing. This fact may allow customers to save additional chemical operating costs.

- Our process creates a heavy metal precipitate which takes a few minutes to form and settle out. The precipitate is then separated from the water. Treated water is sent to a clarifier like a dissolved air(flotation unit (DAF unit) and then the final effluent is filtered with micro-filtration prior to release. The sludge—which passes the toxicity characteristic leaching procedure (TCLP)—can be disposed of in any landfill.

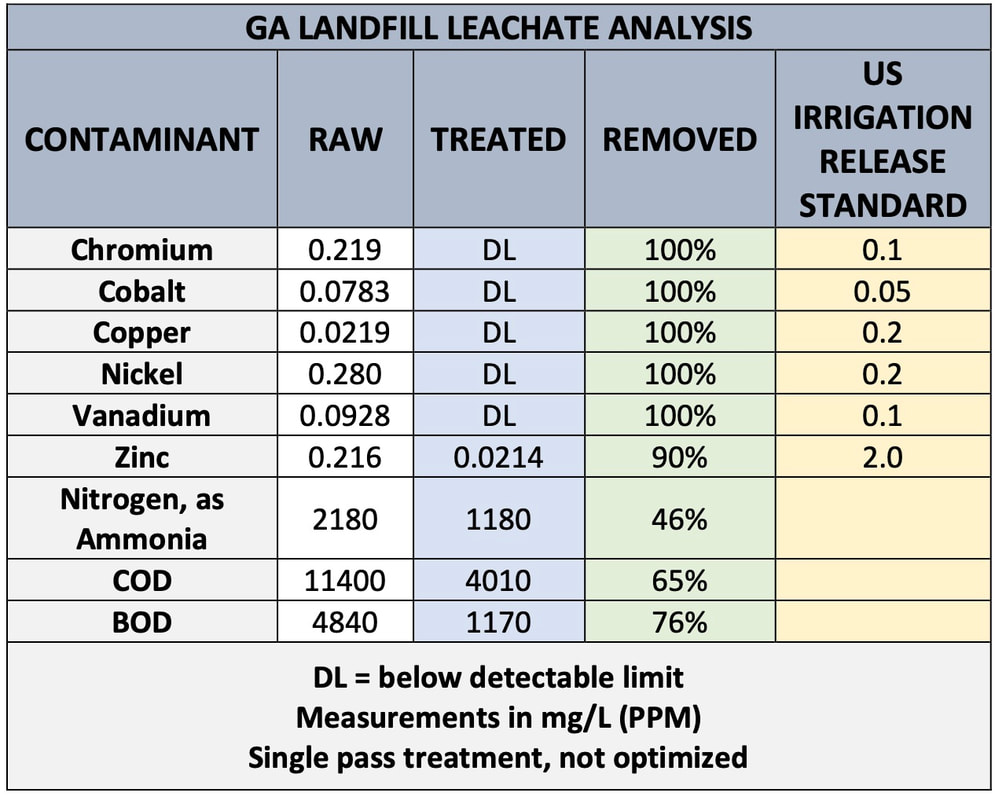

CASE STUDY: GA LANDFILLIn January 2020, Avivid treated a sample from a site in Georgia recognized as producing some of the worst landfill leachate in the industry. Treated effluent was sent to a third-party laboratory for contaminant removal verification. The results are displayed in the chart below. TurboCoag® creates a heavy precipitate which takes a few minutes to form and settle out. The precipitate is then separated from the water, final effluent is filtered. The sludge—which passes the toxicity characteristic leaching procedure (TCLP)—can be returned to the landfill. TurboCoag® is a cost-effective alternative to chemical water treatment via its patented electrocoagulation (EC) reactors. |

TURBOCOAG® KEY FEATURES

|

*Note that EC does not remove dissolved salts, but it is a very practical process prior to reverse osmosis (RO) or any other desalination system since the contaminants that damage RO membranes are removed.